The Importance of Routine Ultrasonic Scaler Maintenance

Is your Cavitron™ dry? Are you having trouble getting water flow out of your ultrasonic scaler? Clogging is a frequent problem with ultrasonic scalers. We hear complaints of no or low water flow almost every day.

Ultrasonic scalers use a lot of water, but also generate a lot of heat, especially magnetostrictive scalers. For more information on type of ultrasonic scalers, check out Practice Tips #10. Scalers have very small water lines (1/16” i.d.). These factors combine to create ideal breeding grounds for biofilm formation. To avoid clogging, routine maintenance of your ultrasonic scaler is crucial.

Reduce the Build-Up of Bacteria

To reduce the number of bacteria Colony Forming Units (CFU’s) in your water lines, there are a number of protocols to follow. This includes installing self-contained water systems (see Practice Tips #55) which shows how easy this can be) and adding a solution (Sterilex or Blu Tabs) to the water. Simply reducing the bacteria count in your water line can be a great first step in reducing the incidence of clogs in your water line.

Additionally, putting a filter on your water inlet further reduces the debris in the water line and lower the likelihood of clogs. There are a number of good filters you can use.

Brass Filters

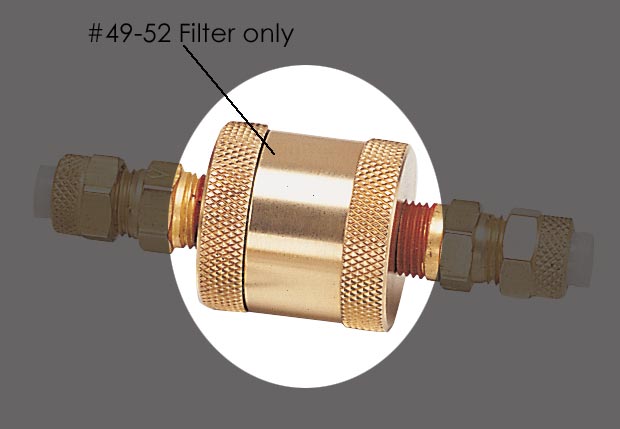

First, there is the time-honored brass filter (#49-50). These have traditionally been used in the junction box, but are readily installed on the ¼” o.d. lines used to supply water to ultrasonic scalers. These filters are inexpensive and easy to install. However, the filter housing is opaque, so it’s not easy to monitor the condition of the filter. Its heavy brass housing so it also pulls on the tubing.

These filters typically filter out particles as small as 35 microns (µm), so they catch a lot of fine debris. The fittings on this filter are not integral, so you can swap them out for other fittings (such as #14-08) to attach to other sizes of tubing.

Other fittings for use with the #49-50 filter are:

Luer Lock Filters

Dentsply™ often provides a disc-type luer lock filter (#49-57) with their ultrasonic units. These filters are used in the medical community to filter IV lines or in similar applications. They offer fine particle filtration and remove particles as small as 20 µm. With these filters, the filter element is permanently locked in a filter housing, making filter changes very quick and easy. However, the filter housing must be discarded with the filter element, adding to the expense of the filter cartridge. The filter housing is transparent, so it’s easy to monitor the condition of the filter making it easier to know when to change the cartridge.

PHOTO: A luer-lock filter cartridge (#49-57).

In-Line Filters

Last of all, American Dental Accessories, Inc. offers a transparent in-line filter (#49-54), which installs easily on ¼” o.d. lines with barbed fittings. This filter removes particles as small as 10 µm to provide superior performance. The filter element is removable from the housing, which reduces the cost of filter replacement (#49-541). The housing is crystal clear, so it’s still a simple matter to monitor the condition of the filter element.

PHOTO: In-line water filter for Cavitron style ultrasonic scalers (#49-54).

LEAVE A REPLY